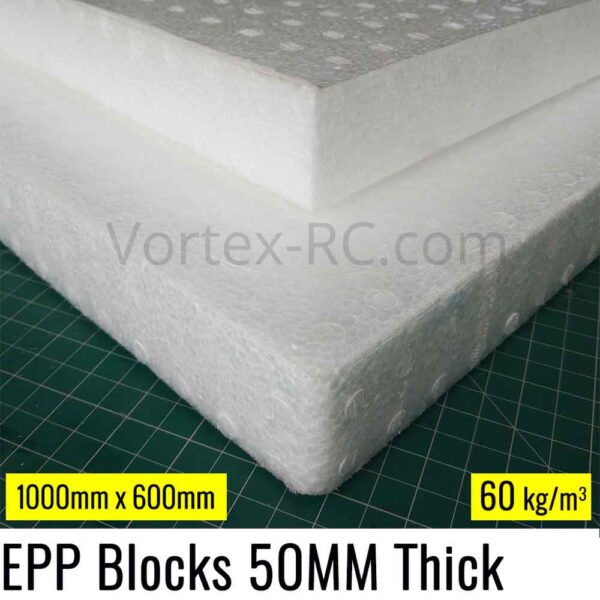

50MM EPP Block 60g/l 1000×600 MM 2 Blocks

₹8,689.00

Sheet Size: 1000mmx600mm

Thickness: 50MM

Density: 60g/l

2 blocks per pack.

- Description

- Additional information

Description

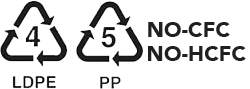

EPP Foam stands for Expanded PolyPropylene. Its a type of foam that is flexible, highly impact resistance, so much so that the sheets can be almost bent without breaking, and has a springy feel to it. It has excellent compression recovery and is almost unbreakable.

EPP foam has an additional advantage : It is compatible with Cyano Acrylate (CA) Glue. This makes it super easy and quick to build RC airplanes and models out of this type of foam.

EPP is best strengthened by thin carbon spars and stringers. Furthermore EPP when skinned with Shipping tape or any adhesive tape becomes very strong.

EPP Foam blocks are great for hot wire cutting wings. Make your own flying wing, or cut out any airfoil of your choice.

EPP Blocks on our site are available in thickness of 50MM with a sheet size of 100cms by 65 Cms, The choice of colour is White and Black. The density of these blocks is 30 Kg/M3 , This is ideal for making RC planes.

We Ship EPP Blocks in a 5-Ply Corrugated box, made specially for this purpose. Due to the size of the box and high Volumetric Weight, All orders will be shipped only by IndiaPost Parcel Service. This is a trackable service and usually delivers within a week to 10 days all over India.

Technical Specifications

- Size: 1000mmx600mm

- Thickness: 50MM

- Density: 60g/l

Quantity

- 2 EPP Foam block per pack

TECHNICAL DATA

|

|

Item

|

Test procedure

|

Grade

|

P30

|

|

|---|---|---|---|---|

| Cell structures | Independence | Independence | ||

| Foam Density | JIS-K6767 | g/cm3 | 0.030 | |

| Comprenssive strength | 25% | NDS-Z0504 | kg/cm3 | 1.50 |

| 50% | 2.30 | |||

| 75% | 5.10 | |||

| Stress-Strain hysteresis | 25% | NDS-Z0504 | % | 4.50 |

| 50% | 8.70 | |||

| 75% | 13.90 | |||

| Permanent Stress by Compression | JIS-K6767 | % | 8.60 | |

| Tensile | Strength | JIS-K6767 | kg/cm3 | 4.30 |

| Elongation | JIS-K6767 | % | 17.00 | |

| Tear strength | JIS-K6767 | kg/cm | 2.60 | |

| Compressive Creep | JIS-Z0235 | % | 1.00 | |

| 230C X 7 day | ||||

| 0.1kgf/cm3 | ||||

| Dynamic Cushiosning Properties | Cushioning factor | JIS-Z0235 | ____ | 2.40 |

| Maximum stress | JIS-Z0235 | kg/cm3 | 3.80 | |

| Surface resistivity | JIS-K6911 | ____ | ||

CHEMICAL RESISTANCE

| Chemicals | Resistance | |

|---|---|---|

| PE | PP | |

| Grease | ++ | ++ |

| Gasoline | + | + |

| Kerosene | ++ | + |

| Engine oil | ++ | ++ |

| Sulfuric acid solution 30% | ++ | ++ |

| Nitric acid solution 10% | ++ | ++ |

| Hydrochloric acid 10% | ++ | ++ |

| Sodium hydroxide solution | ++ | ++ |

| Ammonium solution 10% | ++ | ++ |

| Toluene | +/- | +/- |

| Acetone | ++ | + |

| Ethyl alcohol | ++ | ++ |

| n-Heptance | +/- | +/- |

| Tetrachlorocarbon | +/- | +/- |

| Trichloroethylene | +/- | +/- |

| Ethyl acetate | ++ | ++ |

| Methyl ethyl ketone | + | + |

++ : Very good resistance

+/- : Good resistance

+ : Resistance

– : NO Resistance

Additional information

| Weight | 8 kg |

|---|---|

| Colour | White, Black, 1 White + 1 Black |

| Density | 60 g/l |

| Material | EPP |

| Thickness | 50MM |